Titanium alloy TA1 chubhu inogona kushandiswa i

Titanium Alloy TA1 Tube, Yakagadzirwa netitanium alloy, inogona kupatsanurwa mumhando nhatu zvichienderana nechimiro.(1 Aluminium netin zvinowedzerwa kune titanium. Aluminium, chromium, molybdenum, vanadium nezvimwe zvinosanganiswa nesimbi zvinowedzerwa kune titanium. 3 Titanium ine aruminiyamu uye vanadium nezvimwe zvinhu.)Dzine michina yemhando yepamusoro, zvidhinha zvakanakisa, uye zvinogona kuva akaiswa mumhando dzakasiyana-siyana, kusungirira simba rekubatana kunogona kusvika 90% yesimba rematrix simbi, uye machinability yakanaka.Titanium chubhu ine yakakwira corrosion kuramba kune chloride, sulfide uye ammonia.Kudzivirirwa kwekuora kwetitanium mumvura yegungwa kwakakwira kupfuura iyo yealuminium alloy, simbi isina tsvina uye nickel base alloy.Titanium zvakare ine simba rekudzivirira kwemvura.

Titanium Alloy TA1 Tube, Iyo Yakakodzera Standard

GB/T 3620.1-2016 Titanium uye titanium alloy mamakisi uye kuumbwa kwemakemikari

GB/T 3624-2010 Titanium uye titanium alloy tube standard

Titanium uye titanium alloy machubhu ekuchinjanisa kupisa uye condensers

TA1, TA2 uye TA3 maindasitiri akachena titanium, ane yakakwira michina zvivakwa, yakanakisa stamping zvivakwa, uye inogona kuvezwa nenzira dzakasiyana.Iyo welded joint simba inogona kusvika 90% yesimba rematrix simbi, uye kucheka kuita kwakanaka.Titanium chubhu ine yakakwira corrosion kuramba kune chloride, sulfide uye ammonia.Kudzivirirwa kwekuora kwetitanium mumvura yegungwa kwakakwira kupfuura iyo yealuminium alloy, simbi isina tsvina uye nickel base alloy.Titanium zvakare ine simba rekudzivirira kwemvura.

Inoshandiswa mukugadzira machubhu econdenser mumvura yakasvibiswa yegungwa, mvura ine yakakwira yakaturikwa yakasimba, uye pakuyerera kwakanyanya.

Titanium Alloy TA1 Tube, Classification

Maererano nehistological

1. aluminium uye tin zvinhu zvinowedzerwa kune titanium.

2. alloy zvinhu zvakadai sealuminium, chromium, molybdenum uye vanadium zvinowedzerwa kune titanium.

3. aluminium uye vanadium inowedzerwa kune titanium.

Titanium alloy ine simba rakawanda uye yakaderera density, yakanaka michina zvivakwa, yakanaka kuomarara uye corrosion kuramba.Mukuwedzera: titanium alloy process performance haina kunaka, yakaoma kucheka.Mukugadzirisa kupisa, zviri nyore kwazvo kutora tsvina yakadai sehydrogen, okisijeni, nitrogen uye kabhoni.Iko kune urombo hwekupfeka kuramba, yakaoma kugadzira maitiro.

Yakakamurwa nezvinhu zvakasanganiswa

A alloy yakavakirwa patitanium nezvimwe zvinhu zvakawedzerwa.Kugadzirwa kwemaindasitiri etitanium kwakatanga muna 1948. Zvinodiwa zvekusimudzira indasitiri yezvendege zvinoita kuti indasitiri yetitanium iwedzere paavhareji yekukura kwepagore inosvika 8%.Kuburitswa kwepagore kwetitanium alloy kugadzirisa zvinhu kwasvika kupfuura 40,000 matani, dzinenge makumi matatu marudzi etitanium alloy.Iyo inonyanya kushandiswa titanium alloys ndeye Ti-6Al-4V (TC4), Ti-5Al-2.5Sn (TA7) uye indasitiri yakachena titanium (TA1, TA2 uye TA3).

Maererano ne utility cent

Titanium alloy inogona kupatsanurwa kuita kupisa kusagadzikana alloy, yakakwirira simba alloy, corrosion resistant alloy (ti-molybdenum, ti-Palladium alloy, nezvimwewo), yakaderera tembiricha alloy uye yakakosha basa alloy (ti-iron hydrogen yekuchengetedza zvinhu uye ti-nickel ndangariro. alloy), etc. Maumbirwo uye zvimiro zvearoyi akajairika zvinoratidzwa mutafura.

Titanium Alloy TA1 Tube, Shandisa

Titanium Alloy TA1 Tube, Inonyanya kushandiswa kugadzirwa kwendege injini compressor zvikamu, zvichiteverwa nemaroketi, makomba uye akakwira-kumhanya dhizaini zvikamu.Pakazosvika pakati pemakore ekuma1960, titanium nezviwanikwa zvayo zvakanga zvashandiswa muindasitiri yakajairika kugadzira maelectrodes eindasitiri yemagetsi emagetsi, macondenser ezviteshi zvemagetsi, maheater ekunatsa oiri uye kubvisa munyu mumvura yegungwa, uye midziyo yekudzora kusvibiswa.Titanium uye alloys ayo ave rudzi rwekuora inodzivirira zvimiro zvezvinhu.Uye zvakare, inoshandiswawo kugadzira hydrogen kuchengetedza zvinhu uye chimiro chendangariro alloys.

China yakatanga kudzidza ma<em>titanium ne<em>titanium alloys muna 1956. Pakati pemakore ekuma1960, zvinhu zve<em>titanium zvakagadziridzwa uye zvakagadziridzwa kuita TB2 alloy.

Kuumbwa Kwemakemikari

| Giredhi | N | C | H | Fe | THE | Al | IN | Zvakanaka | Mo | In | Of | Tensile Simba (MPa) | Goho Simba (MPa) | Elongation(%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal | 240 | 138 | makumi maviri nemana |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | Bal | 438 | 345 | 18 |

| Type | Tinogonawo kupa TB3, TB6, TC4, TC6, TC11, TC17,TC18 maererano nezvaunoda. | |||||||||||||

| Standard | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Application | Metallurgy, zvemagetsi, zvekurapa, makemikari, peturu, mishonga, aerospace, nezvimwe. | |||||||||||||

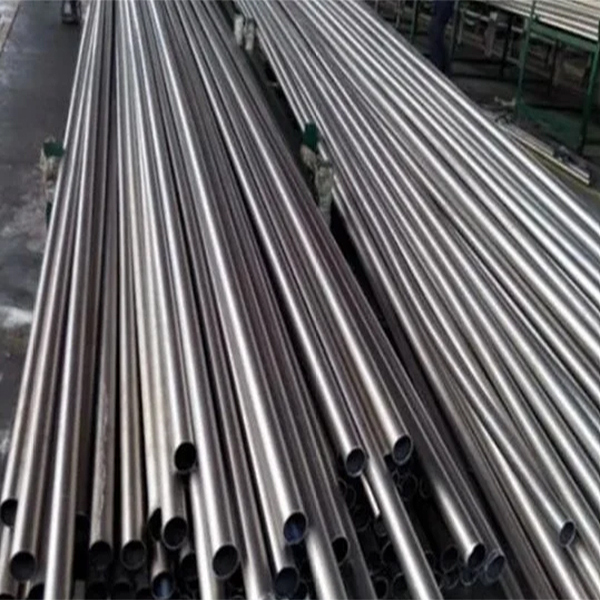

Product Display