Kupisa Yakakungurutswa Seamless Simbi Tube

Kupisa Yakakungurutswa Seamless Simbi Tube, Kupisa kutenderedza kune hukama nekutonhora kukunguruka, kutonhora kukunguruka kuri kukunguruka pazasi petembiricha yerecrystallization, uye kupisa kunopisa kuri kukunguruka pamusoro petembiricha yekudzoreredza.

Kupisa Yakakungurutswa Seamless Simbi Tube, Advantages

Inogona kuparadza chimiro chekukanda chesimbi ingot, kunatsiridza saizi yezviyo zvesimbi, uye kubvisa kukanganisa kweiyo microstructure, kuitira kuti chimiro chesimbi chigadziriswe uye michina yemagetsi inovandudzwa.Kuvandudzwa uku kunonyanya kuratidzwa munzira yekutenderedza, kuitira kuti simbi isisiri isotropic kune imwe nhanho.Mabhubhu, kutsemuka uye kusununguka kwakagadzirwa panguva yekukanda kunogona zvakare kusungirirwa pasi pekushisa kwakanyanya uye kumanikidzwa.

Classification

Inopisa Yakakomberedzwa Seamless Simbi Tube, Yakakamurwa kuita yakajairika simbi pombi, yakaderera uye yepakati kumanikidza boiler simbi pombi, yakakwira boiler simbi pombi, alloy simbi pombi, pombi yesimbi isina tsvina, peturu inoputika pombi, geological simbi pombi uye imwe pombi yesimbi.

Inotonhora yakakungurutswa (dial) isina musono pombi yesimbi kuwedzera kune yakajairika simbi pombi, yakaderera uye yepakati kumanikidza boiler simbi pombi, yakakwira boiler simbi pombi, alloy simbi pombi, simbi isina tsvina pombi, peturu inoputika pombi, imwe simbi pombi, inosanganisirawo kabhoni nhete- pombi yesimbi yakakomberedzwa, alloy yakatetepa-yakakomberedzwa simbi pombi, Stainless simbi pombi, special-shaped simbi pombi.Iyo dhayamita yekunze yepombi inopisa yakakungurutswa isina musono inowanzopfuura 32mm uye ukobvu hwemadziro ndeye 2.5-75mm.Iyo yekunze dhayamita yechando yakakungurutswa isina musono pombi inogona kusvika 6mm uye ukobvu hwemadziro hunogona kusvika 0.25mm.Iyo dhayamita yekunze yepombi yakatetepa-yakakomberedzwa inogona kusvika 5mm uye ukobvu hwemadziro husingasviki 0.25mm.

General musono simbi pombi: yakagadzirwa 10, 20, 30, 35, 45 uye imwe yepamusoro-mhando kabhoni bonded simbi 16Mn, 5MnV uye imwe yakaderera alloy structural simbi kana 40Cr, 30CrMnSi, 45Mn2, 40MnB uye imwe simbi inopisa kana simbi inoputika. chando chakakunguruka.10, 20 uye imwe yakaderera kabhoni simbi yekugadzira isina musono pombi inonyanya kushandiswa pombi yemvura.45, 40Cr uye imwe yepakati kabhoni simbi yakagadzirwa isina musono pombi kugadzira michina zvikamu, senge mota, matirakita akasimbisa zvikamu.Iko kushandiswa kwakajairwa kwesimbi isina musono pombi kuti ive nechokwadi chekusimba uye flattening bvunzo.Mapaipi anopisa akakungurutswa esimbi anounzwa mune inopisa yakakungurutswa kana kupisa inorapwa mamiriro.Cold rolled delivery is heat - treatment.

Inobvumirwa kutsauka kweyakajairika dhayamita yekunze

D1 ± 1.5%, shoma ± 0.75mm

D2 kuwedzera kana kubvisa 1.0%.Minimum +/ - 0.50 mm

D3 + / - 0.75%.Minimum +/ - 0.30 mm

D4 + / - 0.50%.Minimum +/ - 0.10 mm

Simbi chubhu uremu kuverenga formula

[(dhayamita rekunze - ukobvu hwemadziro)* ukobvu hwemadziro]x0.02466=kg/ m (huremu pamamita)

Kupisa Yakakungurutswa Seamless Simbi Tuben, Inoshanda Zvinangwa

1. Chikamu chekuvaka ndeichi: pasi pepombi yekufambisa yakawanda, kuvaka kubviswa kwemvura yepasi, boiler yekufambisa mvura inopisa.

2. Mechanical processing, kutakura sleeve, kugadzirisa michina michina, nezvimwewo.

3. Magetsi: gasi kutapurirana, mvura simba rekugadzira fluid pipeline.

4. Mhepo simba rekudyara antistatic pombi, nezvimwewo.

Tsanangudzo

| Product name | Stainless simbi pombi/chubhu |

| Standard | ASME, ASTM, EN,BS,GB,DIN,JIS nezvimwe |

| Brand | 201/202/304/304L/316/316L/ 321/309S/310S/410/420/430 |

| Chitupa | BV, ISO, CE, SGS nezvimwe |

| Type | Seamless & welded |

| Kunze Diameter (OD) | 3-1220mm |

| Ukobvu | 0.5-50mm |

| Urefu | 6000mm 5800mm 12000mm kana Customized |

| Technique | Cold Drawn kana Hot Drawn |

| Surface | 2B, No.1, No.4, HL, BA, 8K zvichingodaro |

| Application | Indasitiri, makemikari, magetsi, michina, zvivakwa, kushongedzwa, nezvimwewo. |

| Packing | Standard export export-akakodzera kurongedza |

| Delivery Nguva | 7-15 Mazuva ekushanda mushure meDhipositi |

| TradeTerms | FOB, CFR, CIF, EXW |

| Payment Terms | 30%T/T,L/C |

Surface Treatment

| Surface | Tsanangudzo | Application |

| Nha.1 | Iyo yepamusoro inopedzwa nekupisa kupisa uye pickling kana maitiro anoenderana ipapo mushure mekupisa kupisa. | Chemical tank, pombi nezvimwe. |

| Nha.3 | Idzo dzakapedzwa nekukwenenzverwa neNo.100 kusvika kuNo.120 mabrasives anotsanangurwa muJIS R6001. | Midziyo yeKitchen, Kuvaka kuvaka etc. |

| Nha.4 | Idzo dzakapedzwa nekukwenenzverwa neNo.150 kusvika kuNo.180 mabrasives akataurwa muJIS R6001. | Midziyo yeKitche, Kuvaka kuvaka, Midziyo yekurapa nezvimwe. |

| 2B | Idzo dzakapedzwa, mushure mekutonhora kukungurutswa, nekurapa kwekupisa, kunhonga kana kumwe kurapwa kwakafanana uye kwekupedzisira nekutonhora kukungurutsira kupa kwakakodzera kupenya. | Midziyo yekurapa, indasitiri yeChikafu, Zvekuvaka, Midziyo yeKitchen nezvimwe. |

| BA (Nhamba.6) | Avo vakagadziridzwa neyakajeka kupisa kurapwa mushure mekutonhora kukunguruka. | Midziyo yekicheni, Zvishandiso zveMagetsi, Kuvaka kuvaka nezvimwe. |

| Mirror (Nhamba.8) | Kupenya segirazi | Kuvaka kuvaka, kushongedza nezvimwe. |

| Hairline | Idzo dzakapedzwa kukwenenzverwa kuitira kuti dzirambe dzichikwenenzverwa mitsetse nekushandisa abrasive yehukuru hwezviyo hwakakodzera. | Kuvaka Kuvaka etc. |

Kuumbwa Kwemakemikari

| Giredhi | C | Si | Mn | P | S | Ni | Cr | Mo | |||||

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - | |||||

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - | |||||

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - | |||||

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - | |||||

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - | |||||

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - | |||||

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - | |||||

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | ||||||

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0- | |||||

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 - | |||||

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - | |||||

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - | |||||

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - | |||||

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0 · 28.0 | 19.0-23.0 | 4.0-5.0 | |||||

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | |||||

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |||||

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0 .26 | - | |||||

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - | |||||

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - | |||||

| Product Zita | Material | Standard | Saizi(mm) | Application | |||||||||

| Low tembiricha chubhu | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 | GB/T18984- 2003 ASTM A333 | OD: 25mm ~ 508mm WT: 3mm ~ 100mm | Nyorera kune - 45 ºC ~ 195 ºC yakaderera tembiricha yekumanikidza mudziyo uye yakaderera tembiricha yekupisa pombi | |||||||||

| High-pressure boiler tube | 20G ASTMA106B ASTMA210A ST45.8-III | GB5310-1995 ASTM SA106 ASTM SA210 DIN17175-79 | OD:8-1240* WT:1-200 | Inokodzera kugadzira yakanyanya kudzvanywa boiler chubhu, musoro, pombi yehutsi, nezvimwe | |||||||||

| Petroleum inoputika chubhu | 10 20 | GB9948-2006 | OD: 8-630* WT:1-60 | Inoshandiswa mumafuta ekunatsa choto chubhu, kupisa exchanger chubhu | |||||||||

| Yakaderera yepakati pressure boiler chubhu | 10# 20# 16Mn,Q345 | GB3087-2008 | OD:8-1240* WT:1-200 | Inokodzera kugadzira akasiyana masisitimu epasi uye epakati pressure boiler uye locomotive boiler | |||||||||

| General chimiro yechubhu | 10#,20#,45#,27SiMn ASTM A53A,B 16Mn,Q345 | GB/T8162- 2008 GB/T17396- 1998 ASTM A53 | OD:8-1240* WT:1-200 | Nyorera kune yakajairwa chimiro, tsigiro yeinjiniya, mechanic processing, nezvimwe | |||||||||

| Kabati yemafuta | J55,K55,N80,L80 C90,C95,P110 | API SPEC 5CT ISO11960 | OD:60-508* WT:4.24-16.13 | Inoshandiswa kuburitsa oiri kana gasi muoiri Wells casing, inoshandiswa muoiri uye gasi tsime padivi pemadziro | |||||||||

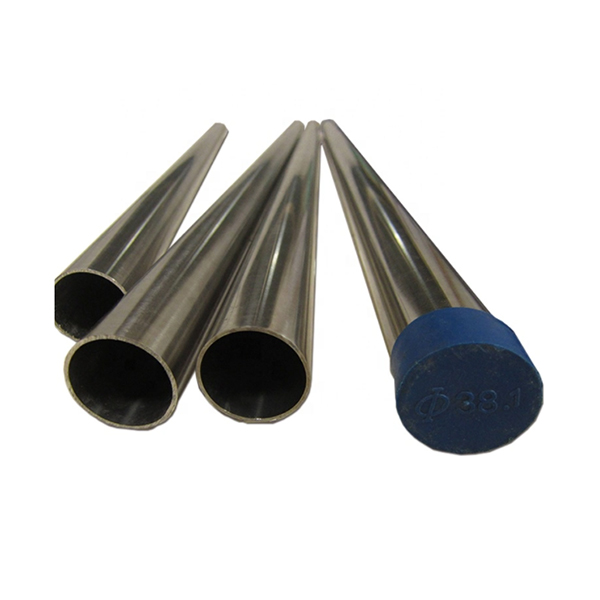

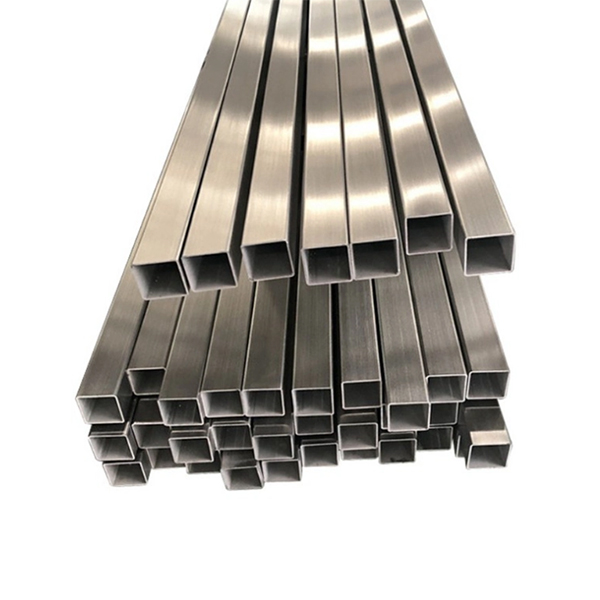

Product Display