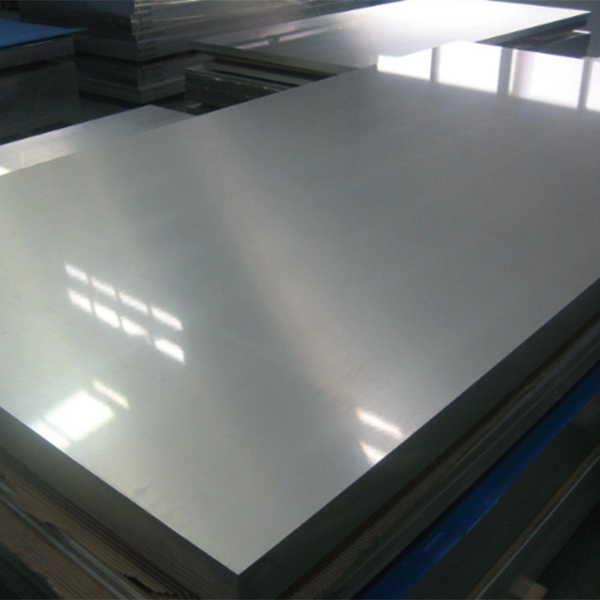

Yakagadzirirwa 304 304L Stainless Steel Plate

Zvimiro zveplate yesimbi isina tsvina

1. Weldability

Kushandiswa kwakasiyana kwechigadzirwa kune zvakasiyana zvinodiwa pakuita welding.Kirasi yetafuraware kazhinji haidi kuita welding, uye inotosanganisira mamwe mabhizinesi ehari.Nekudaro, zvigadzirwa zvakawanda zvinoda kuita kwakanaka kwewelding yezvigadzirwa, seyechipiri-kirasi tableware, thermos makapu, pombi dzesimbi, hita dzemvura, madhishi emvura, nezvimwe.

2. Corrosion resistance

Zvizhinji zvezvigadzirwa zvesimbi zvisina tsvina zvinoda kumira zvakanaka, seKirasi I uye II tableware, midziyo yekubikira, maheater emvura, madhishi emvura, nezvimwewo. Vamwe vatengesi vekunze vanoitawo bvunzo dzekudzivirira ngura pane zvigadzirwa: shandisa NACL aqueous solution kuipisa kusvika pakuvira, woidira pashure penguva yakati.Bvisa mhinduro, geza uye uome, uye uyera kurema kuti uone dhigirii yekuora (Cherechedza: Kana chigadzirwa chakwenenzverwa, iyo Fe yemukati mumucheka weabrasive kana sandpaper inokonzera ngura pamusoro panguva yekuedzwa).

3. Kupenya kuita

Munzanga yanhasi, zvigadzirwa zvesimbi zvisina simbi zvinowanzokwenenzverwa panguva yekugadzirwa, uye zvishoma chete zvigadzirwa senge zvidziya zvemvura uye mvura inodhiza liner hazvidi kukwenenzverwa.Naizvozvo, izvi zvinoda kuti kukwenenzverwa kwechigadzirwa chacho kwakanaka kwazvo.Izvo zvinhu zvikuru zvinokanganisa kuita kwe polishing ndezvizvi:

(1) kuremara kwepamusoro kwezvigadzirwa.Zvakadai sekukwenya, gomba, pickling, nezvimwe.

(2)Dambudziko rezvigadzirwa.Kana iyo kuomarara kwakadzikira, hazvizove nyore kukwenenzverwa kana uchikwenenzverwa (iyo BQ pfuma haina kunaka), uye kana kuomarara kwakadzikira, chiitiko che orange peel chiri nyore kuoneka pamusoro panguva yekudhirowa kwakadzika, zvichikanganisa. iyo BQ pfuma.BQ zvimiro zvine kuomarara kwepamusoro zvakati zvakanaka.

(3) Kune yakadzika-yakadhonzwa chigadzirwa, madiki madiki makwapa uye RIDGING achaonekwa pamusoro penzvimbo ine huwandu hukuru hwe deformation, zvichikanganisa kuita kweBQ.

4. Kudzivisa kupisa

Kupisa kupisa kunoreva kuti simbi isina tsvina inogona kuramba ichichengetedza yakanakisa yemuviri uye michina zvimiro pakupisa kwakanyanya.

Mhedzisiro yekabhoni: Carbon inoumbwa zvakasimba uye yakagadzikana mu austenitic stainless steels.Zvinhu zvinosarudza austenite uye kuwedzera austenite dunhu.Kugona kwekabhoni kugadzira austenite kunosvika makumi matatu kune iyo nickel, uye kabhoni chinhu chinopindirana chinogona kuwedzera zvakanyanya simba reaustenitic stainless simbi kuburikidza nekusimbisa mhinduro yakasimba.Kabhoni inogona zvakare kunatsiridza kushushikana kwecorrosion kuramba kweaustenitic Stainless simbi mune yakanyanya kunyudzwa chloride (senge 42% MgCl2 kuvira mhinduro).

Nekudaro, mu austenitic stainless simbi, kabhoni inowanzoonekwa sechinhu chinokuvadza, kunyanya nekuti pasi pemamwe mamiriro (akadai sewelding kana kupisa pa450 ~ 850 ° C) mukupokana nekuora kwesimbi isina tsvina, kabhoni inogona kudyidzana nekabhoni mumhepo. simbi.Chromium inoumba yakakwira-chromium Cr23C6-mhando kabhoni makomisheni, izvo zvinotungamira mukuderera kwechromium yemuno, iyo inoderedza kushorwa kwesimbi, kunyanya kuramba kune intergranular corrosion.naizvozvo.Mazhinji ezvichangobva kugadzirwa chromium-nickel austenitic Stainless steels kubva kuma1960s akanyanya-yakaderera kabhoni marudzi ane kabhoni ari pasi pe0.03% kana 0.02%.Zvinogona kuzivikanwa kuti sezvo kabhoni yemukati inoderera, iyo intergranular corrosion susceptibility yesimbi inoderera.Kana iyo kabhoni yemukati yakadzikira kupfuura 0.02% ine yakanyanya kujeka mhedzisiro, uye zvimwe zviedzo zvakaratidzawo kuti kabhoni inowedzerawo gomba corrosion maitiro echromium austenitic simbi isina tsvina.Nekuda kwekukuvadza kwekabhoni, kwete chete kabhoni yemukati inofanirwa kudzorwa zvakaderera sezvinobvira mukunyungudutsa kweaustenitic stainless simbi, asiwo mune inotevera nzira yekupisa, kutonhora kushanda uye kupisa kurapwa kudzivirira kuwedzera kwekabhoni pa. pamusoro pesimbi isina tsvina uye kudzivirira chromium carbides Precipitate.

5. Corrosion resistance

Kana huwandu hwemaatomu echromium musimbi isiri pasi pe 12.5%, simba re electrode resimbi rinogona kungoerekana rachinjwa kubva pakusakwanisa kuita maelectrode akanaka.Kudzivirira electrochemical corrosion.

Execution chiyero chesimbi isina tsvina ndiro

Iyo ndiro yesimbi isina tsvina ine nzvimbo yakatsetseka, yakakwira plastiki, kuoma uye kusimba kwemagetsi, uye inoshingirira mukuora nemaasidhi, alkaline magasi, mhinduro uye mamwe midhiya.Isimbi yealloy isingaite ngura nyore, asi kwete zvachose isina ngura.Stainless simbi ndiro inoreva ndiro yesimbi inoshingirira mukuora nemidziyo isina simba yakaita semhepo, chiutsi nemvura, ukuwo acid-resistant steel plate inoreva ndiro yesimbi isingaite ngura nemakemikari anoita corrosive media senge acid, alkali, uye munyu.Stainless simbi ndiro yave iripo kweanopfuura zana kubva payakabuda pakutanga kwezana remakore rechi20.

Stainless simbi ndiro kazhinji izwi rinowanzoreva simbi isina simbi ndiro uye acid-resistant simbi ndiro.Yakaunzwa pakutanga kwezana rino remakore, kuvandudzwa kwesimbi isina tsvina yakaisa zvinhu zvakakosha uye nheyo yehutano yekusimudzira indasitiri yemazuva ano uye kufambira mberi kwesayenzi uye teknolojia.Kune marudzi akawanda emapuleti esimbi ane zvinhu zvakasiyana.Yakagadzira zvishoma nezvishoma mapoka akati wandei muhurongwa hwekuvandudza.

Zvinoenderana nechimiro, yakakamurwa kuita zvikamu zvina: austenitic Stainless simbi, martensitic Stainless simbi (inosanganisira kunaya kwemvura inoomesa simbi isina tsvina), ferritic Stainless simbi, uye austenitic plus ferritic duplex simbi isina tsvina.Iyo hombe kemikari inoumbwa kana zvimwe zvinhu zvine hunhu mundiro yesimbi inoiswa mu chromium Stainless simbi ndiro, chromium nickel Stainless simbi ndiro, chromium nickel molybdenum Stainless simbi ndiro, yakaderera kabhoni Stainless simbi ndiro, yakakwirira molybdenum Stainless simbi ndiro, yakakwirira kuchena Stainless simbi ndiro. , nezvimwewo.

Zvinoenderana nemaitiro uye mashandisirwo emaplate esimbi, akakamurwa kuita nitric acid-resistant stainless steel plates, sulfuric acid-resistant stainless steel plates, pitting-resistain stainless steel plates, stress-resistain stainless steel plates, uye kusimba kwepamusoro. mahwendefa esimbi asina tsvina.Zvinoenderana nemaitiro ekushanda kweplate yesimbi, yakakamurwa kuita yakaderera tembiricha yesimbi isina simbi, isiri-magnetic Stainless simbi ndiro, yemahara-kucheka Stainless simbi ndiro, superplastic Stainless simbi ndiro, nezvimwewo. kune maitiro ekugadzirisa kwesimbi yesimbi, maitiro emakemikari ekugadzirwa kwesimbi yesimbi uye kusanganiswa kwezviviri.

Kazhinji yakakamurwa kuita martensitic Stainless simbi, ferritic Stainless simbi, austenitic Stainless simbi, duplex Stainless simbi uye kunaya kwemvura kuomesa Stainless simbi, nezvimwewo kana kupatsanurwa muzvikamu zviviri: chromium Stainless steel uye nickel Stainless simbi.Yakasiyana-siyana mashandisirwo Mashandisirwo akajairika: pulp uye mapepa emidziyo yekupisa kupisa, michina michina, dhayi michina, firimu kugadzira michina, mapaipi, zvekunze zvezvivakwa munzvimbo dzemahombekombe, nezvimwe.

Iyo ndiro yesimbi isina tsvina ine nzvimbo yakatsetseka, yakakwira plastiki, kuoma uye kusimba kwemagetsi, uye inoshingirira mukuora nemaasidhi, alkaline magasi, mhinduro uye mamwe midhiya.Isimbi yealloy isingaite ngura nyore, asi kwete zvachose isina ngura.

Ukobvu hwetsoka uye ukobvu hwakajairwa hwendiro yesimbi isina tsvina

Ukobvu hwetsoka hunoreva kuti ukobvu chaihwo hauna kunyanya kusiyana nehukobvu hwetioretical (unonziwo label thickness), unova musiyano mudiki usina kunaka.Kana iyo yakarembera ukobvu iri 1.0MM, iyo inodiwa tsoka ukobvu ingangoita 0.98MM-1.0MM, uye ukobvu hwetsoka hunogona kuva Inonzwisiswa se "yakakora zvakakwana", uye chiyero chakakora ndiko ukobvu hwedzidziso.Makoiri echigayo chesimbi anonyorwa kana abva mufekitari, zvichiratidza ukobvu hwedzidziso.Uhu ndihwo hukobvu hwemazuva ose.