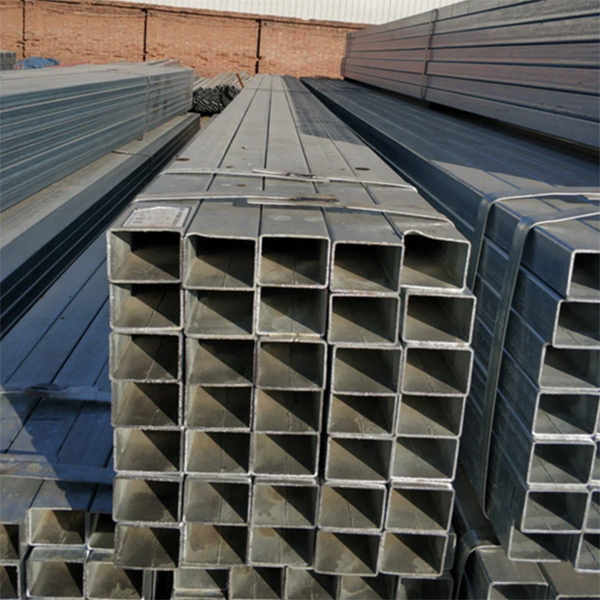

Alloy Square Rectangular Tube

Alloy square rectangular chubhu Iyo inozivikanwawo seskweya uye rectangular inotonhora yakaumbwa isina simbi, inonzi sikweya pombi uye rectangular pombi, kodhi F uye J zvichiteerana.

1. Alloy square rectangular chubhu Kutsauka kunobvumidzwa kwemadziro ukobvu hakupfuurire yakanaka kana yakaipa 10% yezita remadziro ukobvu kana ukobvu hwemadziro huri pasi pe10mm, uye yakanaka kana yakaipa 8% yezita remadziro ukobvu kana ukobvu hwemadziro huri. yakakura kupfuura 10mm, kunze kwekukora kwemadziro kwekona uye weld zone.

2. Alloy square rectangular chubhu Kazhinji kureba kwekutakura ndeye 4000mm-12000mm, ne 6000mm uye 12000mm muhuwandu.Square rectangular chubhu inobvumira kuendeswa kweasingasviki 2000mm zvipfupi uye zvisina kujairika zvigadzirwa, zvinogona zvakare kuendeswa muchimiro chechubhu yehubhu, asi mutengi anofanira kubvisa iyo interface chubhu kana uchishandisa.Huremu hwezvigadzirwa zvehupfupi uye zvisina kurongeka hazvipfuure 5% yehuwandu hwekutakura huwandu, uye kune masikweya rectangular machubhu ane theoretical huremu hunodarika 20kg/m haifaniri kudarika 10% yehuwandu hwekutakura huwandu.

3. Alloy square rectangular chubhu Kukotama hakufanire kunge kwakakura kupfuura 2mm pamamita uye kukotama kwese hakufanirwe kunge kwakakura kupfuura 0.2% yehurefu hwakazara.

4. Alloy square rectangular chubhu Zvinoenderana nemaitiro ekugadzira: inopisa yakakungurutswa isina sikweya chubhu, inotonhora inokweva isina musono square chubhu, kusvina seamless square chubhu, welded square chubhu.

Iyo welded square pombi yakakamurwa kuita

1, zvinoenderana nemaitiro: arc welding square chubhu, kuramba welding square chubhu (yakakwira frequency, yakaderera frequency), gasi welding square chubhu, choto welding square chubhu.

2, maererano ne weld - yakatwasuka musono welding square pombi, spiral welding square pombi.

Alloy Square Rectangular Tube The Material Classification

Square chubhu zvinoenderana nezvinhu: plain kabhoni simbi square chubhu, yakaderera alloy square chubhu.

1, general kabhoni simbi yakakamurwa kuita: Q195, Q215, Q235, SS400, 20 # simbi, 45 # simbi uye zvichingodaro.

2, yakaderera alloy simbi yakakamurwa kuita: Q345, 16Mn, Q390, ST52-3, nezvimwe.

Production Standard Classification

Square chubhu zvinoenderana nemaitiro ekugadzira: gb square chubhu, Japanese standard square chubhu, British system square chubhu, American standard square chubhu, European standard square chubhu, isiri-standard square chubhu.

Chikamu Chimiro Chekuronga

Square mapaipi akaiswa muchikamu zvichienderana nechikamu chimiro:

1, chikamu chakareruka chesquare chubhu: square chubhu, rectangular square chubhu.

2, yakaoma chikamu square chubhu: ruva rakaumbwa square chubhu, yakavhurika square chubhu, corrugated square chubhu, yakaumbwa square chubhu.

Tsanangudzo

| Surface finish | Hunhu & Mashandisirwo |

| NO.1 | Kupisa-yakatenderedzwa pamusoro, yakanyungudutswa uye yakanyungudutswa, inogona kushandiswa sechinhu chinotonhora-inotenderedza, matangi eindasitiri uye chem i cal zvishandiso. |

| NO.2D | Inotonhora-yakakungurutswa, yakanamirwa uye inotungamirwa isina ganda kupfuura yakagomara prod ucts inogona kushandiswa seauto mo bile parts, kuvaka midziyo uye pombi. |

| NO.2B | Kupenya kwepamusoro uye kupfava kweNO.2B kuri nani pane NO.2D.Zvino kuburikidza neakakosha nzvimbo yekuvandudza michina yayo, N02B inogona kuda kugutsa com pre hen sive uses. |

| NO.3 | Yakakwenenzverwa neabra sive belt regrit #100#120,kuve nekupenya kuri nani ne dis con tin u ous coarse stria, inoshandiswa semune nekunze kana zvinhu pakuvaka, elec tri cal ap pli anc es nekicheni uten. sils etc. |

| NO.4 | Yakanatswa nebhandi rinokwesha regrit #150#180, kuve nekupenya kuri nani kune discontinuous coarse stria, asi yakatetepa kupfuura NO.3, inoshandiswa seyemukati yekugezera yemukati neyekunze zvishongo midziyo yemagetsi, midziyo yekubikira uye midziyo yekugadzirisa chikafu nezvimwe. |

| HL | Yakakwenenzverwa nebhandi rinokwesha regrit #150-320 paNo.4 kupera uye ine mitsetse inoenderera, inonyanya kushandiswa sezvishongo zvekuvaka, maelevator, gonhi rechivako, ndiro yepamberi nezvimwe. |

| BA | Inotonhora yakakungurutswa, inopenya yakanamirwa uye ganda rakapfuura, chigadzirwa uct chakanakisa kupenya kupenya uye yakanaka reflex iv i ty segirazi, rinoshandiswa midziyo yemagetsi, girazi, kitch en midziyo, kana ma te ri als nezvimwe. |

Pipe Grade Data Sheet

| Alloy | UNS | Tsanangudzo |

| 304/304L | S30400/S30403 | Chromium-Nickel austenitic alloy inoshandiswa mune zvekutengesa zvikumbiro. |

| 304 | S30400 | Chromium-Nickel austenitic alloy inoshandiswa mune zvekutengesa zvikumbiro. |

| 304L | S30403 | Chromium-Nickel austenitic alloy inoshandiswa mune zvekutengesa zvikumbiro. |

| 304H | S30409 | Chromium-Nickel austenitic alloy inoshandiswa mune zvekutengesa zvikumbiro. |

| 316/316L | S31600/S31603 | Molybdenum-bearing austenitic stainless simbi iyo inoshingirira kune general corrosion uye pitting/crevice corrosion. |

| 316 | S31600 | Molybdenum-bearing austenitic stainless simbi iyo inoshingirira kune general corrosion uye pitting/crevice corrosion. |

| 316L | S31603 | Molybdenum-bearing austenitic stainless simbi iyo inoshingirira kune general corrosion uye pitting/crevice corrosion. |

| 316H | S31609 | Molybdenum-bearing austenitic stainless simbi iyo inoshingirira kune general corrosion uye pitting/crevice corrosion. |

| 309S | S30908 | Austenitic Stainless simbi inowanzo shandiswa kune yakakwira tembiricha maapplication. |

| 309H | S30909 | Austenitic Stainless simbi inowanzo shandiswa kune yakakwira tembiricha maapplication. |

| 310S | S31008 | Austenitic Stainless simbi inowanzo shandiswa kune yakakwira tembiricha maapplication. |

| 310H | S31009 | Austenitic Stainless simbi inowanzo shandiswa kune yakakwira tembiricha maapplication. |

| 317 | S31700 | Molybdenum-bearing austenitic stainless steels ayo anoshingirira kune general corrosion uye pitting/crevice corrosion pane akajairwa chromium-nickel austenitic stainless steels. |

| 317L | S31703 | Molybdenum-bearing austenitic stainless steels ayo anoshingirira kune general corrosion uye pitting/crevice corrosion pane akajairwa chromium-nickel austenitic stainless steels. |

| 317LMN | S31726 | Fully austenitic, nitrogen-bearing, high-molybdenum Stainless steel inoshandiswa munzvimbo dzakakwirira-chloride. |

| 321 | S32100 | Simbi yakagadzika isina tsvina iyo inopa kumira kwakanaka kune intergranular corrosion zvichitevera kuratidzwa kwetembiricha muchromium carbide kunaya kubva pa800 kusvika 1500 ° F. |

| 321H | S32109 | Simbi yakagadzika isina tsvina iyo inopa kumira kwakanaka kune intergranular corrosion zvichitevera kuratidzwa kwetembiricha muchromium carbide kunaya kubva pa800 kusvika 1500 ° F. |

| 347 | S34700 | Simbi yakagadzika isina tsvina iyo inopa kwakanakisa kuramba kune intergranular corrosion zvichitevera kuratidzwa kune tembiricha muchromium carbide kunaya kubva pa800 kusvika 1500 ° F. |

| 347H | S34709 | Simbi yakagadzika isina tsvina iyo inopa kwakanakisa kuramba kune intergranular corrosion zvichitevera kuratidzwa kune tembiricha muchromium carbide kunaya kubva pa800 kusvika 1500 ° F. |

| 348 | S34800 | Simbi yakagadzika isina tsvina iyo inopa kwakanakisa kuramba kune intergranular corrosion zvichitevera kuratidzwa kune tembiricha muchromium carbide kunaya kubva pa800 kusvika 1500 ° F. |

| 348H | S34809 | Simbi yakagadzika isina tsvina iyo inopa kwakanakisa kuramba kune intergranular corrosion zvichitevera kuratidzwa kune tembiricha muchromium carbide kunaya kubva pa800 kusvika 1500 ° F. |

| AL 611 | S30601 | Yakaderera-kabhoni, silicon ine, austenitic Stainless simbi inowanzo shandiswa kunyorera muindasitiri yemakemikari. |

Product Display