A513 square simbi chubhu yekutakura mvura

A513 Steel Square Tubing, Gobvu madziro square simbi pombi, hombe dhayamita square simbi pombi, musono sikweya simbi pombi, yakaderera alloy square simbi pombi, 135 * 135 * 10 square simbi pombi, tower crane square simbi pombi, Q345B yakaderera alloy square simbi pombi, 20 # isina musono sikweya simbi nyere

A513 Steel Square Tubing, Sezvinoreva zita, iri square chimiro chechubhu, marudzi mazhinji ezvinyorwa anogona kugadzira sikweya chubhu muviri, yepakati mukati, chii chekushandisa, kupi kushandisa, yakawanda yeskweya chubhu kune simbi pombi. kune ruzhinji, kunyanya kune structural square chubhu, yekushongedza square chubhu, kuvaka square chubhu uye zvichingodaro.

A513 Steel Square Tubing, Izita reskweya chubhu, inova chubhu yehurefu hwakaenzana.Yakagadzirwa nesimbi ye strip mushure mekugadzirisa nekukunguruka.Kazhinji, mutsara wacho unobudiswa, wakaenzana, wakaoma uye wakasungirirwa muchubhu yakatenderera, iyo inokungurutswa muskweya chubhu uye yozochekwa muhurefu hunodiwa.Kazhinji zvimiti makumi mashanu papakiti.

A513 Steel Square Tubing, Kune isina musono uye weld mapoinzi, isina musono square chubhu ndiyo isina musono chubhu extrusion molding.Square simbi pombi, gobvu madziro square simbi pombi, hombe dhayamita square simbi pombi, musono square simbi pombi, yakaderera alloy square simbi pombi, 135 * 135 * 10 square simbi pombi, tower crane square simbi pombi, Q345B yakaderera alloy square simbi pombi, 20 # isina musono square simbi pombi

1. Exponential performance analysis of square tubes - plasticity

Plasticity inoreva kugona kwesimbi kugadzira deformation yepurasitiki (permanent deformation) pasina kukuvara pasi pemutoro.

2. Performance index analysis of square tube - kuoma

Hukukutu (hardness in English) chiyero chekuti simbi yakaoma kana kuti yakapfava zvakadii.Parizvino, iyo inonyanya kushandiswa nzira yekuona kuomarara mukugadzira ndiyo indenter kuomarara nzira, iri kushandisa imwe geometric chimiro cheindenter musoro pasi pemumwe mutoro mukati meiyo yakaedzwa simbi zvinhu, zvinoenderana nedhigirii indenter kuona kukosha kwayo kwekuoma.

Nzira dzinowanzo shandiswa dzinoti Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) neVickers hardness (HV) nedzimwe nzira.

3. Performance index analysis of square tube - kuneta

Simba, plasticity, uye kuoma kwataurwa pamusoro apa zviratidzo zvemakanika zvivakwa zvesimbi pasi pekurodha.Muchokwadi, akawanda emuchina zvikamu anoshanda pasi pema cyclic mitoro, uye kuneta kunogona kuitika pasi peaya mamiriro.

4. Performance index analysis ye square pombi - kukanganisa kuoma

Kuremerwa kunoshanda pazvikamu pakumhanya kwakanyanya kunonzi kukanganisa kurodha, uye kugona kwesimbi kuramba kukuvara pasi pemutoro wekukanganisa kunonzi kukanganisa kuoma.

5. Square pombi performance performance index analysis - simba square simbi pombi, gobvu madziro square simbi pombi, hombe dhayamita square simbi pombi, seamless square simbi pombi, yakaderera alloy square simbi pombi, 135 * 135 * 10 square simbi pombi, tower crane square simbi pombi. , Q345B yakaderera chiwanikwa mativi simbi pombi, 20# musono mativi simbi pombi

Simba ndiko kugona kwesimbi zvinhu kuramba kutadza (yakanyanyisa deformation yepurasitiki kana kutyoka) pasi pekurodha.Nekuda kwemaitiro ekurodha muchimiro chekutambanudza, kudzvanya, kukotama, kuveura, saka simba rakakamurwa kuita simba rekusimba, simba rekumanikidza, kukotama simba, kugera simba uye zvichingodaro.Panowanzo kuve nekubatana pakati peakasiyana masimba, uye simba rekusimba rinowanzo shandiswa seyakanyanya kukosha simba pointer.

Size

| Saizi neInch (dhayamita) | Ukobvu | Saizi neMM (dhayamita) | Ukobvu |

| inch | inch | mm | mm |

| 1/2" x 1/2" | 0.065" | 16mm × 16mm | 0.4mm ~ 1.5mm |

| 3/4" x 3/4" | 0.049" | 18mm × 18mm | 0.4mm ~ 1.5mm |

| 0.065" | 20mm × 20mm | 0.4mm ~ 3mm | |

| 0.083" | 22mm × 22mm | 0.4mm ~ 3mm | |

| 0.120" | 25mm × 25mm | 0.6mm ~ 3mm | |

| 1" x 1" | 0.049" | 30mm × 30mm | 0.6mm ~ 4mm |

| 0.058" | 32mm × 32mm | 0.6mm ~ 4mm | |

| 0.065" | 34mm × 34mm | 1mm ~ 2mm | |

| 0.072" | 35mm × 35mm | 1mm ~ 4mm | |

| 0.083" | 38mm × 38mm | 1mm ~ 4mm | |

| 0.095" | 40mm × 40mm | 1mm ~ 4.5mm | |

| 0.109" | 44mm × 44mm | 1mm ~ 4.5mm | |

| 0.120" | 45mm × 45mm | 1mm ~ 5mm | |

| 1 1/8" x 1 1/8" | 0.035" | 50mm × 50mm | 1mm ~ 5mm |

| 0.049" | 52mm × 52mm | 1mm ~ 5mm | |

| 0.065" | 60mm × 60mm | 1mm ~ 5mm | |

| 0.109" | 70mm × 70mm | 2mm ~ 6mm | |

| 0.120" | 75mm × 75mm | 2mm ~ 6mm | |

| 1 1/4" x 1 1/4" | 0.049" | 76mm × 76mm | 2mm ~ 6mm |

| 0.065" | 80mm × 80mm | 2mm ~ 8mm | |

| 0.072" | 85mm × 85mm | 2mm ~ 8mm | |

| 0.083" | 90mm × 90mm | 2mm ~ 8mm | |

| 0.109" | 95mm × 95mm | 2mm ~ 8mm | |

| 0.120" | 100mm × 100mm | 2mm ~ 8mm | |

| 0.135" | 120mm × 120mm | 4mm ~ 8mm | |

| 0.156" | 125mm × 125mm | 4mm ~ 8mm | |

| 0.188" | 130mm × 130mm | 4mm ~ 8mm | |

| 1 1/2" x 1 1/2" | 0.049" | 140mm × 140mm | 6mm ~ 10mm |

| 0.065" | 150mm × 150mm | 6mm ~ 10mm | |

| 0.072" | 160mm × 160mm | 6mm ~ 10mm | |

| 0.083" | 180mm × 180mm | 6mm ~ 12mm | |

| 0.109" | 200mm × 200mm | 6mm ~ 30mm | |

| 0.120" | 220mm × 220mm | 6mm ~ 30mm | |

| 0.140" | 250mm × 250mm | 6mm ~ 30mm | |

| 0.188" | 270mm × 270mm | 6mm ~ 30mm | |

| 0.250" | 280mm × 280mm | 6mm ~ 30mm | |

| 1 3/4" x 1 3/4" | 0.065" | 300mm × 300mm | 8mm ~ 30mm |

| 0.083" | 320mm × 320mm | 8mm ~ 30mm | |

| 0.095" | 350mm × 350mm | 8mm ~ 30mm | |

| 0.109" | 380mm × 380mm | 8mm ~ 30mm | |

| 0.120" | 400mm × 400mm | 8mm ~ 30mm | |

| 0.188" | 420mm × 420mm | 10mm ~ 30mm | |

| 2" x 2" | 0.049" | 450mm × 450mm | 10mm ~ 30mm |

| 0.065" | 480mm × 480mm | 10mm ~ 30mm | |

| 0.083" | 500mm × 500mm | 10mm ~ 30mm | |

| 0.109" | 550mm × 550mm | 10mm ~ 40mm | |

| 0.120" | 600mm × 600mm | 10mm ~ 40mm | |

| 0.145" | 700mm × 700mm | 10mm ~ 40mm | |

| 0.165" | 800mm × 800mm | 10mm ~ 50mm | |

| 0.188" | 900mm × 900mm | 10mm ~ 50mm | |

| 0.250" | 1000mm × 1000mm | 10mm ~ 50mm | |

| 0.312" | |||

| 2 1/4" x 2 1/4" | 0.188" | ||

| 0.250" | |||

| 2 1/2" x 2 1/2" | 0.083" | ||

| 0.109" | |||

| 0.120" | |||

| 0.188" | |||

| 0.250" | |||

| 0.312" |

| 3" x 3" | 0.083" |

| 0.120" | |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 3 1/2" x 3 1/2" | 0.120" |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 4" x 4" | 0.083" |

| 0.120" | |

| 0.156" | |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" |

| 4 1/2" x 4 1/2" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 5" x 5" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 6" x 6" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 7" x 7" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" |

| 8" x 8" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 9" x 9" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 10" x 10" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 12" x 12" | 0.250" |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 14" x 14" | 0.312" |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 16" x 16" | 0.312" |

| 0.375" | |

| 0.500" | |

| 0.625" |

Kemikari Kuumbwa Kwezvinhu

| Giredhi | element | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | C% max (Norminal WT(mm) | Si% max | Mn% max | P% max | S% max | N% max | |

| uye IC10 | ≤ 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.040 | 0.040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.040 | 0.040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Mechanical Properties Yezvinhu

| Giredhi | Goho Simba | Tensile Simba | Elongation |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norm | Goho Simba | Tensile Simba | Min.elogation | Min.percent properties | ||||||||

| Acc.to EN10027/1 uye IC 10 | Acc.to EN10027/2 | Norminal WTmm | Norminal WTmm | Longit. | Muchinjikwa | Yedza tembiricha°C | Avhareji min.impact value | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | Norminal WTmm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Equivalent Specifications

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | - | St E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EE | - |

| S355NH | E 355 R | St E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EE | - |

| S460NH | E 460 R | St E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EE | - |

- block letter "S" zvinoreva "STEEL FOR STRUCTURAL APPLICATIONS"

- iyo inotevera figure inoreva minim.goho kukosha kunodiwa kumadziro ukobvu ≤16 mm

- "J2" zvinoreva kukosha kwekuedza -20 ° C min.27 joule

- block letter "H" zvinoreva "HOLLOW SECTION".

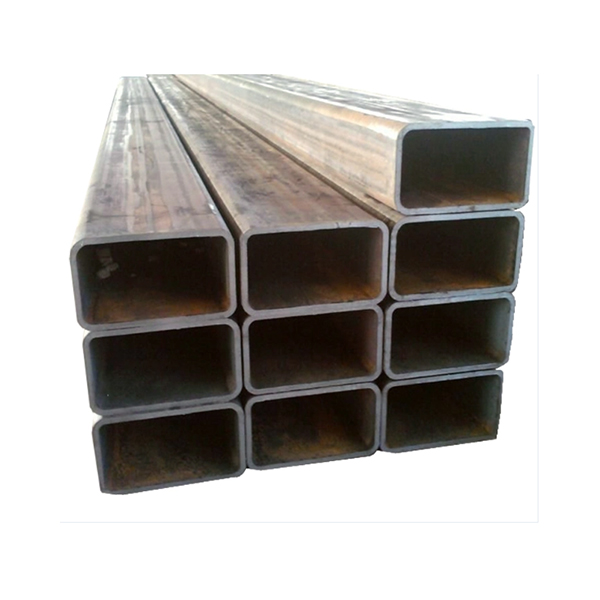

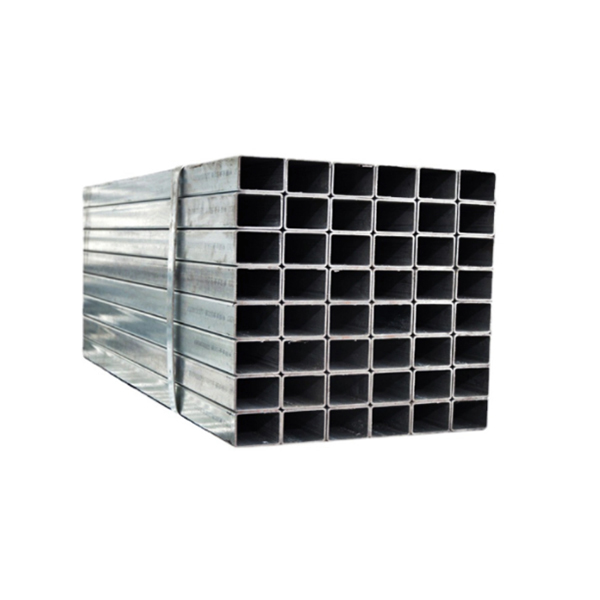

Product Display